Dielectric Option for ARES

A. Franck, TA Instruments Germany

Keywords: dielectric option, ARES, SMT, DETA,

The ARES DETA (Dielectric Thermal Analyzer) is an accessory which expands the testing capabilities of the ARES strain controlled rheometer to include investigations of the dielectric response of materials. This ability to probe the conductive and capacitive nature of test specimens enlarges the range of applications of the ARES rheometer as a universal instrument in material characterization.

FULLY INTEGRATED DIELECTRIC MEASUREMENTS

The ARES DETA option is an accessory which is readily engaged or disengaged from the standard ARES rheometer. Used with the forced convection oven, and ARES parallel plate tools, the DETA accessory measures the dielectric properties of a material while the sample is at rest or undergoing a deformation. Other features of ARES testing are not hindered by the addition of the DETA accessory, and changeover time is under five minutes.

PRINCIPALS OF DIELECTRIC ANALYSIS

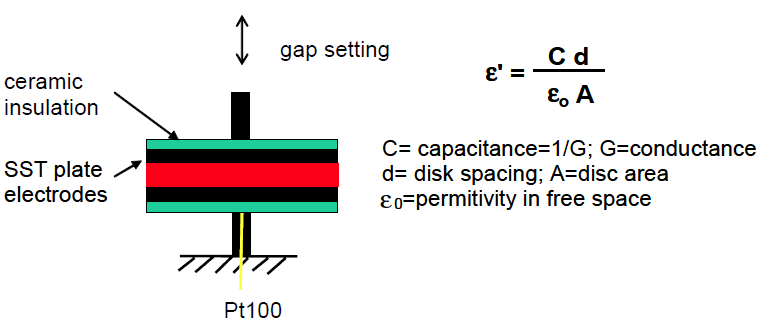

The reorientation of dipoles in an oscillating electric field represents the basis of the dielectric thermal analysis (DETA). The ARES rheometer provides the measuring cell consisting of insulated parallel plates enclosed by the air convection oven. The gap is set manually or automatically via the AutoTension function (Figure 1) . A dielectric bridge (HP 4284A) imposes a dielectric signal of preselected voltage and frequency (Figure 2). The LCR meter measures the capacitance and dielectric loss of the sample. From these measurements the permitivity ε and the dielectric loss tangent tanδ are calculated. The capacitance C represents the electrical charge stored across the potential difference of the two parallel plates. The conductance =1/C is the ability of a material to pass a charge through the sample. The dielectric constant or permitivity ε* is the ratio of a capacitor (the parallel plates of the ARES rheometer) which contains a sample versus one with no sample. The imaginary portion of the signal represents the loss factor ε “ and ε “/ ε ‘ the dielectric loss tan δ. The dielectric properties of a material change significantly with temperature and frequency during transitions in the material, similar to the DMA (Dynamic Mechanica Analysis) measurement.

Figure 1: Dielectric measuring cell

BENEFITS OF DETA

Figure 2: Dielectric option with HP bridge

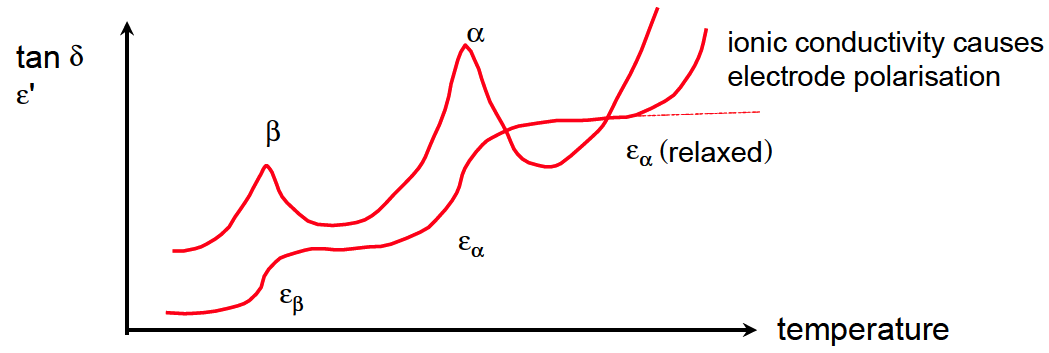

Figure 3: Generic behavior of an amorphous polymer

DETA is more sensitive than DMTA to local motions along the polymer chain since the polar bonds (such as C=O) are affected by the electrical field. The changes in the dielectric constant of a material are quite large and easily detected during phase transformations, side chain relaxations, curing, and decompositions, as compared to the small changes in enthalpy, volume or heat capacity of other more common thermal analytical techniques. Ferroelectric materials with a high dielectric constant are particularly well suited to DETA measurements.

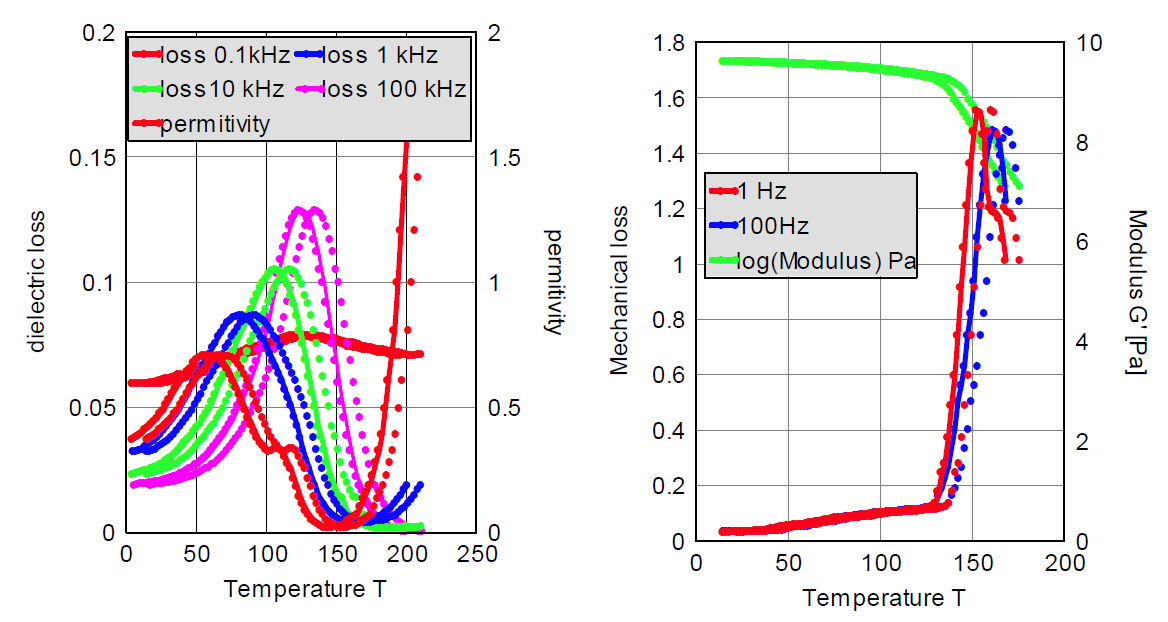

Figure 3 shows the generic behavior of the permitivity and the loss tangent for an amorphous material as a function of temperature. The permittivity increases with increasing temperature. The transitions can be related to side group dynamics and the loss tangent peaks are generally broad compared to DMA. The á relaxation is associated with the polymer chain backbone motion and provides a dielectric measurement of the glass transition Tg. Above Tg the dipoles are free to orientient according to the imposed electrical field. Tan ä increases above Tg due to small conduction losses and the permitivity rises as a result of electrode polarization due to increasing conductivity. Figure 4 shows the mechanical and dielectric response for PMMA as a function of temperature in the range from 0 to 250 oC. As expected both, the transitions measured by dielectric and mechanical probing increase with increasing probing frequency. The á relaxation which is related to the backbone mobility occurs for the same probing frequency of 100Hz at a lower temperature (Tg) in figure 5. This is to be expected, as the relaxation mechanisms probed by the mechanical deformation are not exactly the same probed in the dielectric measurement. The transition is very strong in dielectric, due to the dipole associated with the side chain .

Figure 4: Dielectric and mechanical response for PMMA as function of temperature and frequency